Announcement

Collapse

No announcement yet.

tube or tubeless tyres for 1980 Suzuki's?

Collapse

X

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter

Super Site Supporter- Oct 2003

- 17515

- Indianapolis

Great pictures, Bob!

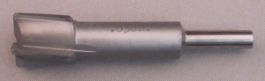

I use a 5/8" counterbore with a 5/16" pilot to machine the flat valve seat. It takes maybe five seconds in a cordless drill.

I ordered these several years ago from an aviation tool supplier.

Looks like they have good used ones in stock cheap right now:

I paid a bit more for new stuff, but one could set oneself up for wheel conversion pretty cheap this way.Last edited by bwringer; 12-13-2020, 07:50 PM.1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

Comment

-

Forum GuruPast Site Supporter

Super Site Supporter- Jun 2018

- 6153

- Mifflinburg, PA / Land of Tar & Chip

OK, tire is off the wheel, took longer than I thought it would. I Suppose it gets easier with practice. The hole mics at .328” (8.35mm). The recess in the underside .571” (14.5mm). So looks like the NAPA one Bob showed in the pic above will work. Was hoping to find a 90 deg valve but can’t seem to find one. Anyone else have a lead?

Corrosion is not terrible I think. These Dremel bits make short work of it, but they wear quickly and I’m out. Ordering more. I’ve got about half the wheel done and I’m fairly confident I can make it acceptable.

You can see the part I’ve done on the right, still yucky on the left. Yes I put a few dings in the edge of the rim with the tire irons when I didn’t have something there to protect the rim. Live and learn.

Live and learn.

I have questions about bead sealant/paste, goes by other descriptions as well. Do I need this? If so, what to use. I realize there will be differing experiences and opinions.Links

Comment

-

A 5/16" would have been better, as that is closer to the correct size of 8mm, but I couldn't find a cheap one...(LOL...At the GSR stereotype).Originally posted by bwringer View PostGreat pictures, Bob!

I use a 5/8" counterbore with a 5/16" pilot to machine the flat valve seat. It takes maybe five seconds in a cordless drill.

I ordered these several years ago from an aviation tool supplier.

Looks like they have good used ones in stock cheap right now:

I paid a bit more for new stuff, but one could set oneself up for wheel conversion pretty cheap this way.

The counterbore I linked had a 9mm pilot, which worked fine, but I needed to clearance the hole a bit.Bob T. ~~ Play the GSR weekly photo game: Pic of Week Game

'83 GS1100E ~ '24 Triumph Speed 400 ~ '01 TRIUMPH TT600 ~ '67 HONDA CUB

Comment

-

You can use a lot of things to ease the tyre on - for years I used hand soap. Don't use dish soap, as the common thickener in that is salt; very bad for the rim.

Recently I bought a tub of pukka tyre soap, with freebie brush. The 5kg tub will last me a lifetime. It certainly makes things quicker and easier.

To clean up the last really grungy rim, it was so bad I had to put a 3" cup wire brush on an angle grinder and attack it all the way around. Luckily, there was no pitting or anything seriously wrong, it was just sticky, manky grungy gunge.Last edited by Grimly; 12-13-2020, 09:33 PM.Dave

'79 GS850GN '80 GS850GT

Only a dog knows why a motorcyclist sticks his head out of a car window

Comment

-

Woho this gets more interesting..

Can I ask a dumb a&% question for the

lesser tech people on site:

- when we say modify the rim we mean

simply changing with a drill bit the valve

area (making is flat to recieve the valve)

Not really making the hole bigger.

It is simply making the hole surround flat for a good seal

of the valve.

-and that in no way changes the profile I.e. the

small bump in proper tubeless rims . see pic.

20201211_180650.jpg

-and why buy a valve as they have throw away ones

in any ture shop that they change on each new tyre?

[I'll ask my other question later .... re how

on earth can you manually get the tyre off ?

I ended up shouting at the devil on my hands and knees

dribbling trying to get a ride on mower ture off)Last edited by ukjules; 12-14-2020, 05:31 AM.UKJULES

---------------------------------

Owner of following bikes:

1980 Suzuki GS550ET

1977 Yamaha RD 250D

1982 Kawasaki GPZ 750 R1

1980 Suzuki GSX 250E

Comment

-

Last edited by ukjules; 12-14-2020, 06:05 AM.UKJULES

---------------------------------

Owner of following bikes:

1980 Suzuki GS550ET

1977 Yamaha RD 250D

1982 Kawasaki GPZ 750 R1

1980 Suzuki GSX 250E

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter

Super Site Supporter- Oct 2003

- 17515

- Indianapolis

Rubber valve stems are standard on almost all modern motorcycles with tubeless tires. The correct size is usually 412, the shortest style. 413 valve stems work fine and are much easier to find; they're just 1/4" longer. I keep 412 stems on hand because they must be replaced when the tires are replaced.Originally posted by rphillips View PostI'm scratching my head, trying to remember a rubber valve stem on a motorcycle wheel. Probably there, I just don't remember them.

FWIW, I would avoid the common practice of installing aluminum right angle valves... they look nice, but they're quite fragile, and the o-ring seals are not very reliable. Rubber valve stems are resilient and pretty much bulletproof.

Correct; as in Bob's pictures above, some vintage cast wheels manufactured before tubeless tires were common are curved on the inside. You need a flat surface on the inside of the wheel so that the rubber sealing washer can seat. The wheel should not be modified in any other way.Originally posted by ukjules View PostWoho this gets more interesting..

Can I ask a dumb a&% question for the

lesser tech people on site:

- when we say modify the rim we mean

simply changing with a drill bit the valve

area (making is flat to recieve the valve)

Not really making the hole bigger.

It is simply making the hole surround flat for a good seal

of the valve.

-and that in no way changes the profile I.e. the

small bump in proper tubeless rims . see pic.

[ATTACH=CONFIG]62082[/ATTACH]

-and why buy a valve as they have throw away ones

in any ture shop that they change on each new tyre?

[I'll ask my other question later .... re how

on earth can you manually get the tyre off ?

I ended up shouting at the devil on my hands and knees

dribbling trying to get a ride on mower ture off)

Do NOT make the hole bigger; the idea is to cut just enough to make a flat area. (And if the surface is already flat, as in some rear wheels, you don't need to do anything; you don't need to make a recess.)

The flat area needs to be 16mm (which is almost exactly 5/8") and the valve stem hole is a little over 8mm (almost exactly 5/16").

Also, FWIW, your photos are showing spoked wheels which are made from extrusions and cannot be converted to tubeless use; we are discussing cast wheels here.

(Yes, there are people who are experimenting with adhesive sealers to seal spoked wheels; this is not what we are discussing and success is spotty at best.)

The rubber valve stems used on most modern bikes use a much larger hole. I don't think it's a good idea to drill the hole larger in vintage wheels.

Also, when installing a metal valve stem, be very careful about how much you compress the rubber sealing washer. It should be compressed by about 1/3, not squashed until it splits.

I replace metal valve stems every five years; that's about the limit of how long you should trust the rubber washer. I suppose you could just replace the rubber washers, but I've never bothered.

As I mentioned above, rubber valve stems on modern bikes always get replaced along with the tires.

And then there are a few modern bikes with TPMS, which is a whole 'nuther ball ache; you mainly just have to be aware there's a sensor in there and work around it. The seals in these should be changed with every tire change.

Changing tires is a skill like any other, and you get better at it with experience. If you're having trouble or getting frustrated, STOP what you're doing and THINK before you damage a wheel or tire. 99% of the time, you're not managing the other side of the tire correctly; the bead MUST be down into the center of the wheel.

You don't need an expensive, bulky machine. After some experience, you can change a tire nearly as fast or faster with tire irons and a simple stand. I was considering a No-Mar, but using one did not impress me in the least, and the urge quickly faded.

Tires on small diameter wheels as on garden tractors are the most challenging by far. Larger diameter tires, as on a GS front wheel, are the easiest of all; just a big bicycle tire.

Close... the first is the wrong diameter. You need 16mm (or 5/8").Originally posted by ukjules View Postis this the sort of thing

[ATTACH=CONFIG]62083[/ATTACH]

https://www.ebay.co.uk/itm/1pc-4Flut...tionMarkerEnd~

The second is just the counterbore. You'll also need the pilot that goes into the 1/8" (3.2-is mm) hole in the counterbore. The pilot will need to be one with a 1/8"/3.2mm shaft and a 5/16" (8mm) nose.

Agreed; I've dealt with the damage dish detergent does to wheels many times and it is not pretty or pleasant. It's extremely corrosive stuff. Even on modern bikes with powder coated wheels, detergent can attack via a tiny scratch.Originally posted by Grimly View PostYou can use a lot of things to ease the tyre on - for years I used hand soap. Don't use dish soap, as the common thickener in that is salt; very bad for the rim.

Recently I bought a tub of pukka tyre soap, with freebie brush. The 5kg tub will last me a lifetime. It certainly makes things quicker and easier.

To clean up the last really grungy rim, it was so bad I had to put a 3" cup wire brush on an angle grinder and attack it all the way around. Luckily, there was no pitting or anything seriously wrong, it was just sticky, manky grungy gunge.

A jug of real tire mounting lubricant costs very little, works wonderfully, and will last most riders for many years. (In the USA, RuGlyde from Napa is the most widely available.) There's no reason at all to fart around with homemade concoctions or other inappropriate substitutes (Windex, WD-40, silicone spray, furniture polish, etc.), but for some reason this practice is very common.

If you're really in a pinch, a very weak solution of the mildest, simplest soap you can find (NEVER a detergent like shampoo) can work, but it won't have the anti-corrosion additives found in real tire mounting lubricant. Murphy's oil soap is fairly common in the US (and Murphy's does make a version of their soap specifically for mounting tires), and some mild hand soaps or saddle soaps can work as well.

One of the biggest reasons for learning to mount your own motorcycle tires is that you can take the time to clean up the sealing surfaces; shops never, ever do this. When I started doing my own tires, I noticed a huge difference in the rate of pressure loss. I thought it was normal to lose 4 or 5 psi in a week.

I would say to use the least damaging method possible to clean up the wheels. A wire brush is pretty drastic, but once in a while it's necessary. I usually scrub with WD-40 soaked into a rough cloth or perhaps a piece of dish sponge or teflon-safe scotch-brite.Last edited by bwringer; 12-14-2020, 09:14 AM.1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

- Likes 1

Comment

-

Forum GuruPast Site Supporter

Super Site Supporter- Jun 2018

- 6153

- Mifflinburg, PA / Land of Tar & Chip

Jules

Out of a desire to do as much of my own work as possible on my bike, I decided to attempt to remove the tire myself using tire irons, sweat, a yes, a lot of swearing. I've always had a local small motorcycle shop do my tire changes. I'm glad I did it. I was looking for a 90 deg. valve but can't find one for the stem hole size, and I wanted something a little better that what the shop would put in. I didn't go to my normal shop for a valve because, well, as great as the guy is with bikes, and I've never complained about all the things I've had him do (rebuilt my carbs perfectly and cheap), he can be kind of a jerk, so I avoid him if possible. The local chain tire shop in my town is dead to me after a botched alignment job on my MINI.

I found the same or very nearly the same valves on Amazon that Bob posted above from NAPA. I'm probably overthinking all of it, like I usually do. But I do not want to drill the hole larger. We'll see how it goes. I have a few days off over the next few weeks, so I have some time to work on it. Not in a hurry. Too cold and wet right now, and an impending big snow storm on the way later in the week.Links

Comment

-

You shouldn't have to, if you get the one Brian suggested, with a 5/16" pilot. (Or 8mm)Originally posted by Rich82GS750TZ View PostI found the same or very nearly the same valves on Amazon that Bob posted above from NAPA. I'm probably overthinking all of it, like I usually do. But I do not want to drill the hole larger. We'll see how it goes.

Stock, the hole in mine was slightly larger than 8mm, so the one I bought with a 9mm pilot worked.

Note: I didn't drill it larger, I just let the 9mm pilot clearance the hole a bit.Bob T. ~~ Play the GSR weekly photo game: Pic of Week Game

'83 GS1100E ~ '24 Triumph Speed 400 ~ '01 TRIUMPH TT600 ~ '67 HONDA CUB

Comment

-

If you find the NAPA one, I can verify it will work...Originally posted by Rich82GS750TZ View PostThe measurement of the flat area I took may be a little off (14.5mm. needs to be 16mm). I'll wait until I have the new valve and see if the rubber fits in the recess before doing anything more drastic.

Bob T. ~~ Play the GSR weekly photo game: Pic of Week Game

Bob T. ~~ Play the GSR weekly photo game: Pic of Week Game

'83 GS1100E ~ '24 Triumph Speed 400 ~ '01 TRIUMPH TT600 ~ '67 HONDA CUB

Comment

-

Wont have that in uk but anyway all I/we need is a m8*16mm

counterbore bit IF my rim needs it to fit a tubeless tyre.

As for valves they have plenty in tyre places

as would only do it in an emergency [unless

as some say it is possible ...]

Getting the tyre off I might give it a go as I

need a new tyre right now.

I have asked this question before on another thread years ago

and discovered the levers to carry with on

long adventures. never bought em or used em mind.

I'll have to find that thread and the levers type

the bottom line is I would prob use that aerosol

gunge to fix tube or tubeless tyres if in peril

on the spanish deserts ...... and get to a town.

As I rode through the plains or spain in the rain

i thought if i get a puncture I'm screwed.

I attach pic of one of my break downs in 2016,

some of you may remember. this was in amsterdam

and with the assistance of this forum in real time

managed to get going again in 7days....

7 days in amsterdam . what a place to break down !

Field garage 1_resize_30.jpgUKJULES

---------------------------------

Owner of following bikes:

1980 Suzuki GS550ET

1977 Yamaha RD 250D

1982 Kawasaki GPZ 750 R1

1980 Suzuki GSX 250E

Comment

.png)

Comment