However, Rustybronco mentioned here about using a LM2917 frequency to voltage converter and redesigning the board, and after some research decided to run with that.

First, I pulled the tach and got it on my bench. You can see the infamous black chip.

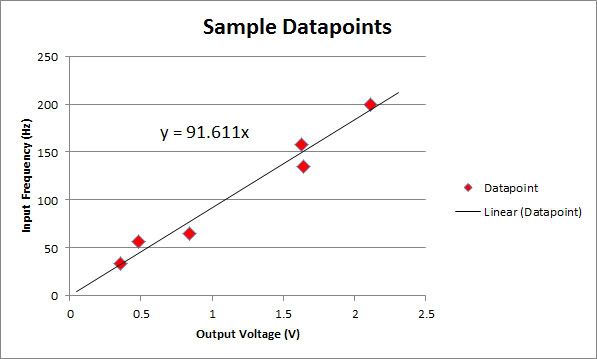

Next, I fed the tach a few DC voltages and visually mapped out the deflection of the needle. Since this is done by eye, there is a small amount of error here but could be reduced with more points. You can see the data points I found (and one from one of the original posts) on the graph below:

The X-axis is voltage, and the Y-axis RPM / 60. The red dots are each sample point, and the black line is a linear regression model which is included in excel. Then we just take the slope of the line, and use that as the design parameters for the LM2917 circuit:

I've added a zener voltage regulator to the input to protect the circuit and ensure the source is steady, since the output is a function of the input. Finally, wired everything up and gave it a square wave to mimic the signal off the coils...And it works! I took a bunch of sample points off the circuit and plotted them on the original graph:

Honestly looks better/more linear than I expected, the response time to a changing input frequency is immediate, and the signal is steady. I've got pics of the circuit but it's just on a breadboard for now. I also hooked it up directly to the tach and it drove the needle without a problem.

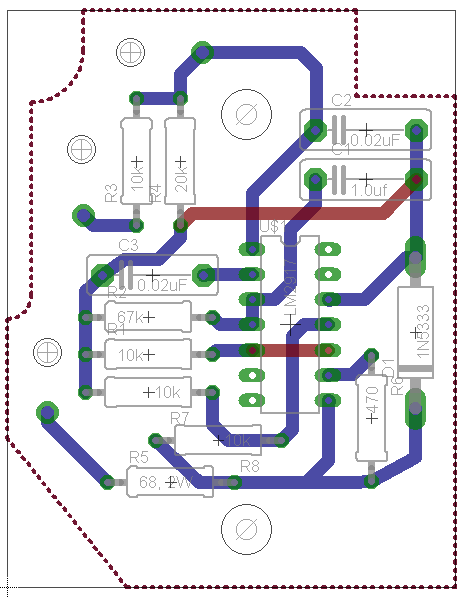

Sparkfun has one-off PCBs, so the next step is getting the design in software and getting a board or two made that it will be a direct swap for the stock board...I'll update as I get there but wanted to show my progress so far

Comment