Announcement

Collapse

No announcement yet.

Project Windjammer

Collapse

X

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35985

- Torrance, CA

Awesome link Dale!!! Going to make one of these before shooting any more nasty isocyanate paint.Originally posted by rustybronco View PostEd

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

-

Billyboy

Billyboy -

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter- Jul 2005

- 15156

- Marysville, Michigan

Thanks Ed! making up something like that, a pair of goggles and using a 'tyvek' suit (or cheap rain suit) should keep you relatively safe.Originally posted by Nessism View PostAwesome link Dale!!! Going to make one of these before shooting any more nasty isocyanate paint.Last edited by rustybronco; 03-03-2011, 02:50 PM.

Comment

-

Matchless

Matchless

Originally posted by rustybronco View PostThen building something like this will be in order. http://www.sonerai.net/CMS/index.php...id=56&Itemid=1

I like that! I have just thrown my old respirator away! Excellent solution though!

I think will do the windshield bending before any painting, to minimize any scratching of the new paintwork. So the next job will be building the oven and the mold and doing a test bend to get the proper minimum temperature and check the performance before I commit a full size bit of polycarbonate.

Comment

-

Matchless

Matchless

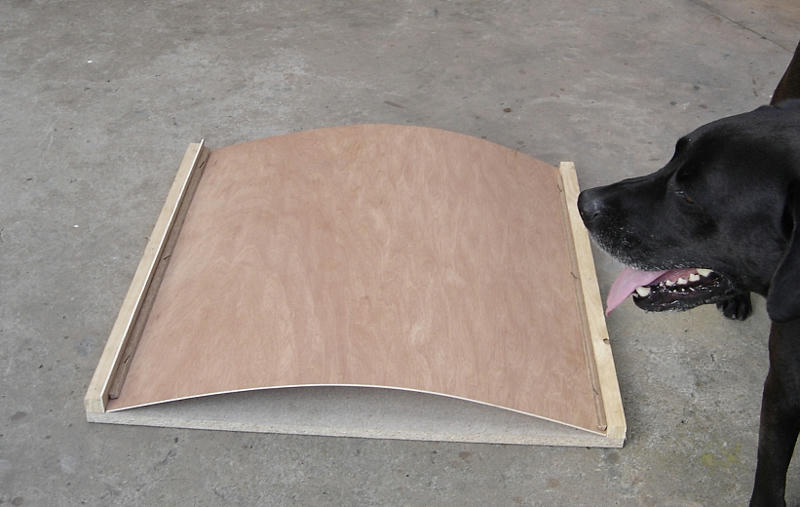

The mold is not completed yet. Once I have the exact curvature then some support will be put under the plywood. The plan is to fabricate an oven that will accommodate the mold with an adjustable thermostat and a digital thermometer. The idea is then to heat the polycarbonate to the minimum heat required to bend it over the plywood and then let it cool down slowly with some weights on the two outer sides.

The cutting to shape will only be done after the bending.

Any advice will be appreciated.

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter- Jul 2005

- 15156

- Marysville, Michigan

The wood fibers in your forming surface may leave an slight impression in the Naxel. depending on the heating temperature I used when I 'unformed/reformed' the old windscreen, the plywood surface left an impression during my 'testing' on it. because of this possibility I would suggest a smoother surface (thin sheet metal?) added to the top of your plywood surface.Originally posted by Matchless View PostAny advice will be appreciated.

Comment

-

Billyboy

Billyboy -

Matchless

Matchless

Thanks Dale that is one of my worries as I have seen a lot of mention of impressing the surface of the Naxel. Do you think a metal surface would not get hotter than the wood? I could easily clad it with aluminum flashing. What do you think of HT paint on the wood?

I will definitely have to support the plywood, but will do once I have the correct radius on the bend.

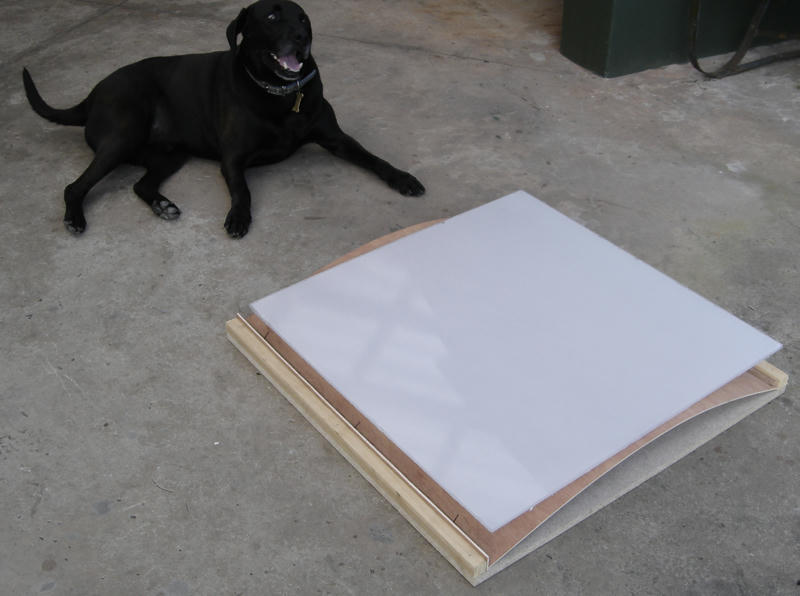

Yes, Georgie follows me around all over and joins in whatever I do or plonks himself down in my way! He is quite photogenic! So rather than trying to shoo him out of the photo I left him and now he thinks he should be in everyone!

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter- Jul 2005

- 15156

- Marysville, Michigan

Andre,Originally posted by Matchless View PostThanks Dale that is one of my worries as I have seen a lot of mention of impressing the surface of the Naxel. Do you think a metal surface would not get hotter than the wood? I could easily clad it with aluminum flashing. What do you think of HT paint on the wood?

While the wood and metal may arrive at forming temps with differing rates, in an oven they will eventually be at the same temp. preheat the form, attach the Lexan then bring up the temp slowly. my 3 cents worth Dr...

***edit*** the coefficient of expansion between wood and metal will differ. but for practical intents and purposes, how much it will matter might not be enough to worry about.Last edited by rustybronco; 03-04-2011, 01:27 PM.

Comment

-

Matchless

Matchless

I will do a test run on a small bit, as I also need to determine the minimum temperature at which it will just start becoming bendable.Originally posted by rustybronco View PostAndre,

While the wood and metal may arrive at forming temps with differing rates, in an oven they will eventually be at the same temp. preheat the form, attach the Lexan then bring up the temp slowly. my 3 cents worth Dr...

***edit*** the coefficient of expansion between wood and metal will differ. but for practical intents and purposes, how much it will matter might not be enough to worry about.

I will go for the sheet metal cladding as that would be easiest.

Next is the oven. I need to find a useful thermostat for the element I have.

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter- Jul 2005

- 15156

- Marysville, Michigan

I think what you need to test for is, at what temp does it form easily without bubbling. on the little test I did, when the Lucite reached thermoforming temp you could easily bent it with two fingers!Originally posted by Matchless View PostI will do a test run on a small bit, as I also need to determine the minimum temperature at which it will just start becoming bendable.

I will go for the sheet metal cladding as that would be easiest.

Next is the oven. I need to find a useful thermostat for the element I have.

here's a 'frugal' method you can use to regulate temp in your 'oven'. watch your temp gauge (probe) and 'regulate' power to your element with a switch. the ultimate down and dirty method of regulation. or, just find an old stove and snitch the control from it.

or, just find an old stove and snitch the control from it.

Comment

-

Matchless

Matchless

If you look at my first picture of the pod and radio on the bike, in the background I have a small oven. I will test a small bit in there to see what temperature I should aim for. Apparently the window of opportunity that I want on the polycarbonite is a bit smaller than the perspex and at a higher temperature around 150 C, but need to prove that.

I never even thought of manual regulation as a way to go for a once off. I may even do that.

What is your thoughts on spraying the plywood mold with high temperature engine enamel from a rattlecan (supposed to withstand up to 600 Deg F) and then sanding it to a smooth finish?

I was thinking of using a pair of gloves to push/droop it manually over the mold when it just becomes flexible instead of waiting for it to gravity droop mold, thus staying as far as possible from the bubble forming temperature range.

I can get a sheet of 4mm Asbestos cement 900mm x 2400mm that is used in ceilings and intend making a box for the oven from that with 6 pieces of 900mm x 400mm. I am worried that the height of the 3 KW element above the Naxel may allow less even heat to the outer edges and without a fan may cause the center to become hotter than the outer part and cause bubbles.

Comment

.png)

Comment