Thanks,

Rear master cylinder rebuild

Collapse

X

-

Rear master cylinder rebuild

One of the things that I can do on my project during the winter is rebuilding my rear brake master cylinder. It is all there, but the seals seem to be shot. I have not even taken it off the bike yet. I did a bit of searching and looked at Basscliff's site, but found nothing on rebuilding the rear master cylinder. Any help out there?

Thanks,Tags: None -

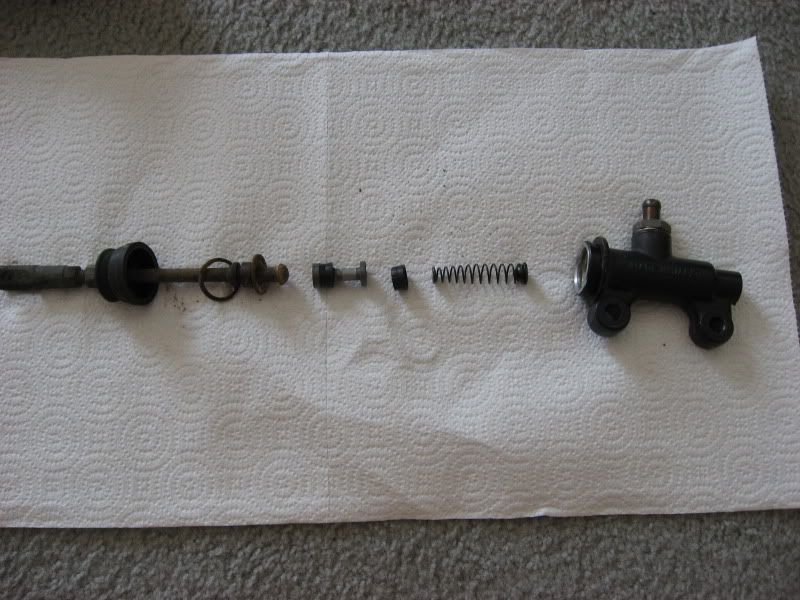

It's pretty simple. Take it off the bike and tear it down. Clean everything and replace the rubbers with OEM, if you can get them. Push a strand of wire through the tiny breather hole in the main body - it almost certainly has crud in it. It's easily missed and the unit will not work properly if it's not clean.One of the things that I can do on my project during the winter is rebuilding my rear brake master cylinder. It is all there, but the seals seem to be shot. I have not even taken it off the bike yet. I did a bit of searching and looked at Basscliff's site, but found nothing on rebuilding the rear master cylinder. Any help out there?

Thanks,

Have confidence, you can do this easily.

Take digital photos as you go, makes it easy to remember how it goes back together!-Mal

"The only reason for time is so that everything doesn't happen at once." - B. Banzai

___________

78 GS750E -

Do a search on here and you'll find tons of threads about it. But basically Allojohn has it right.

Make sure you bleed everything properly.Cowboy Up or Quit. - Run Free Lou and Rest in Peace

1981 GS550T - My First

1981 GS550L - My Eldest Daughter's - Now Sold

2007 GSF1250SA Bandit - My touring bike

Sit tall in the saddle Hold your head up high

Keep your eyes fixed where the trail meets the sky and live like you ain't afraid to die

and don't be scared, just enjoy your ride - Chris Ledoux, "The Ride"Comment

-

Inspect the aluminum master bore for pitting. If corrosion has set in, the master can not be rebuilt.

Ed

Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-ResurrectionComment

-

7981GS

7981GS

If you don't have a two stone wheel cylinder hone, you can roll various grits of sandpaper up and hone it with that.

DanielComment

-

snyderman

snyderman -

I wouldn't bother to hone an aluminum GS master. Honing is good to clean up cast iron automotive master cylinders, but not aluminum masters. The GS master cylinder bore is highly polished from new and any abrasives you put inside only degrade the surface finish and reduce seal life.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-ResurrectionComment

-

7981GS

7981GS

Pessimism and "I have never done that" or "had any success with that myself", strikes again!

It works and I have been doing it for over 35 years.

DanielComment

-

The stock finish is something like Ra<8. This is a very smooth finish - equal to polishing with something like 600 grit sandpaper.

Putting a grinding hone inside an aluminum master cylinder bore will degrade this finish significantly and should be avoided. A rough finish will wear the rubber plunger pieces.

The only reason to hone a master cylinder is if there is contamination on the surface of the metal. When a aluminum GS master cylinder corrodes the damage goes down into the metal forming a pit. Sanding over the top of the pit does no good.

I don't care if someone has been doing something wrong for 35 years without consequence. Doing something wrong is doing something wrong.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-ResurrectionComment

-

7981GS

7981GS

Sorry to hear that some people just can't repair much of anything.

Just buy new OEM parts and be happy.

After all, nothing works on these bikes but OEM, right? LMAO!!!

DanielComment

-

There are 1000s of good rear MCs out there and they're cheaper than buying the bloody sandpaper!79 GS1000S

79 GS1000S (another one)

80 GSX750

80 GS550

80 CB650 cafe racer

75 PC50 - the one with OHV and pedals...

75 TS100 - being ridden (suicidally) by my fatherComment

-

Thanks for reminding me Daniel...

Original Suzuki brake system seals (master cylinder kits/seals, caliper seals/pistons) are WAY better quality than commonly available K&L parts. In many cases the OE parts are cheaper as well. Two times I wasted considerable time farting around with brake system problems only to eventually trace the issue to crappy K&L parts. Consider this an official warning. Ed

Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-ResurrectionComment

-

To the OP, lets see what the factory has to say about the matter...

and the service limits as stated in the GS1000 service manual...using a piece of wood or soft metal, push the internals out of the cylinder bore, taking care not to nick or scratch the bore wall

you can take that for what its worth.bore standard 14.0mm (.551 in) service limit 14.05mm (.553 in)

to 7981GS, yes I have sanded 'many' a master cylinder/ wheel cylinder bore over the years. did I have 100% success at it? no. would I try sanding the bore on my own bike? sure, and I have. would I recommend else to polish out anything more than a 'light' pitting on there own equipment? no.Comment

-

99% accurate. You can get better, stainless steel pistons (well we can anyway ). Non OEM rubber isn't - it's jelly. It's junk.

79 GS1000S

). Non OEM rubber isn't - it's jelly. It's junk.

79 GS1000S

79 GS1000S (another one)

80 GSX750

80 GS550

80 CB650 cafe racer

75 PC50 - the one with OHV and pedals...

75 TS100 - being ridden (suicidally) by my fatherComment

-

1_v8_merc

1_v8_merc

I've Used K&L on all my bikes...Never had any of these "problems".....

You guys make it sound like the brakes will fail at 1,000 miles!

My advice to the OP...install what you can afford.

You want Good brakes...switch to stainless steel lines...THAT'S well worth the money!

I have the same bike as you, the Rear Master Cylinder is the EASY one, lol.

I think I have photos of the Tear-down for this bike.Last edited by Guest; 01-26-2012, 04:26 PM.Comment

Comment